Why Is Traditional Validation No Longer Enough?

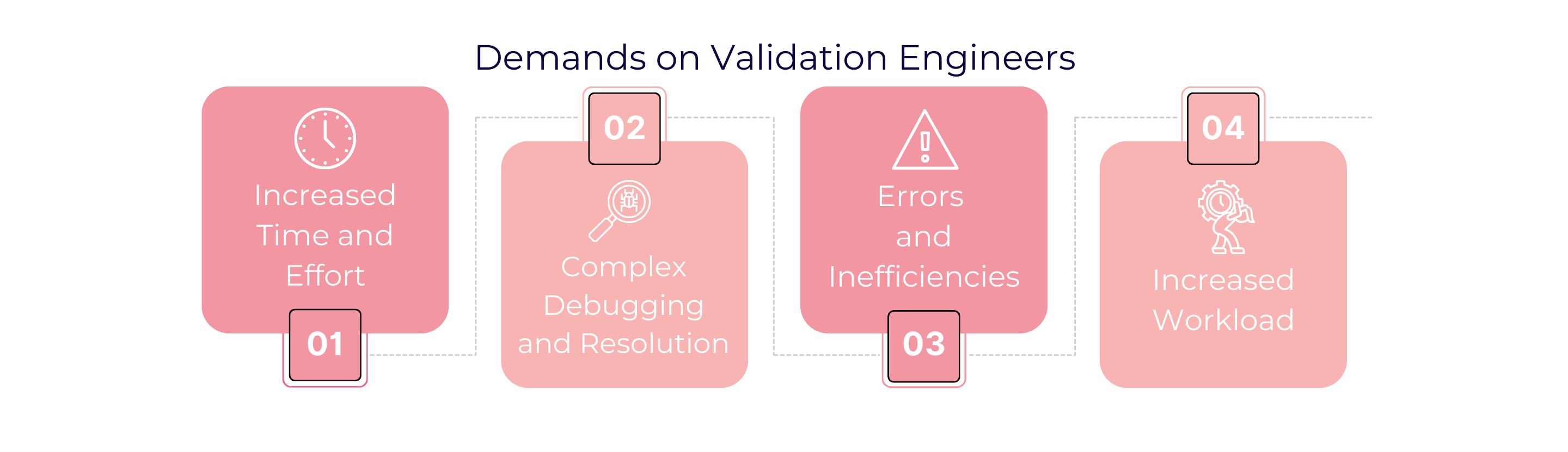

Traditional validation processes, though straightforward in theory, can burden validation engineers either with the process or with test equipment.

- Increased Time and Effort: Building a test setup to cover most of the tests can take several weeks or months to complete, stretching timelines and affecting product release schedules.

- Complex Debugging and Error Resolution: Engineers must sift through extensive logs to pinpoint issues, frequently re-run tests, and record errors. This cycle can lead to burnout and delays, slowing the entire product development cycle.

- Higher Chance of Errors and Inefficiencies: Engineers must traverse oscilloscopes and record the measurements manually. This process of manual measurement can be error-prone and introduce inconsistencies in the validation process.

- Increased Workload Due to Automation Gaps: While some steps are semi-automated, others require custom API development and extensive integration work. Engineers often spend more time programming and managing execution than actively focusing on validation.

The tools used in conventional validation have limitations that can further challenge the validation engineer and constrain testing capabilities.

- Limited Specification Coverage: Benchtop instruments, such as protocol analyzers and debuggers, are generally limited to basic functional tests. They may fall short of comprehensive parametric validation, particularly in electrical and timing aspects, making it difficult to validate the device thoroughly.

- Challenges with Automation and Reliability: Many benchtop tools lack integration capabilities for seamless software test automation. This makes reproducing results with the reliability required for protocol compliance challenging.

When basic bench tools fall short, validation engineers may turn to Automated Test Equipment (ATE) for more in-depth testing. However, ATEs require significant technical expertise to set up and operate, adding considerable cost and effort to the validation process. This setup involves creating protocol-specific design patterns and requires skilled analysis to interpret results.

This level of complexity and equipment dependency underscores the need for a more streamlined and efficient solution. One that allows engineers to achieve full protocol validation without extensive manual effort, software development, or costly equipment.